Unveiled at bauma 2025, the new Liebherr LTM 1150-5.4E mobile crane with electric drive meets the requirements of ‘zero emissions construction sites’, combining sustainability with maximum efficiency. This 150-t crane is equipped with a telescopic boom of up to 66-m long.

On and off-road, a 400-kW combustion engine with Stage 5 exhaust emission provides for powerful drive. The motor is fully compatible with hydrogenated vegetable oil (HVO) and, compared to diesel fuel, reduces operational CO2 emissions by up to 90%.

In crane operation, the choice between combustion engine or electric motor allows flexible use. The latter reduces both air and noise emissions to a minimum and is ideal for ‘zero emissions areas, as well as noise-sensitive areas.

Flexible use

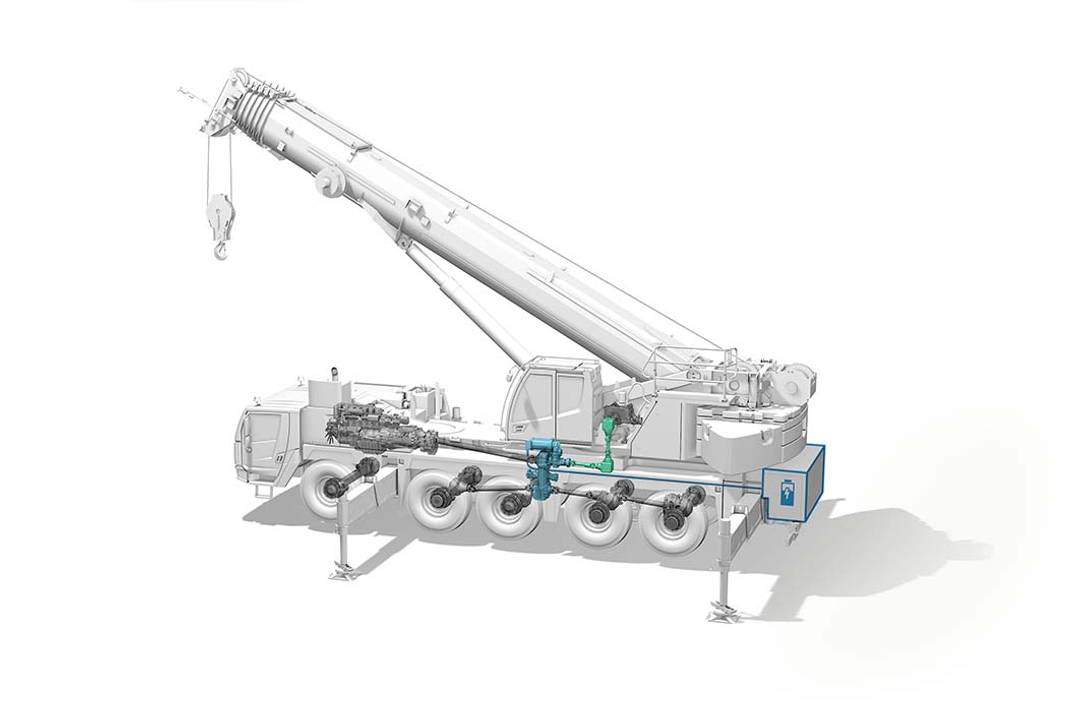

The newly developed drive features a 111-kW electric motor, which guarantees unlimited crane operation, offering virtually the same performance as the six-cylinder combustion engine. For the transfer of power to the consumers in the crane superstructure, the electric drive uses the existing gear shafts from the transfer gearbox in the chassis to the pump transfer gearbox in the superstructure.

The electric version complements the conventional model of the LTM 1150-5.4 with a water-cooled high-speed electric motor, a distributor gear, a battery and the necessary control technology. The electric motor’s distributor gear is integrated cleverly between the chassis transfer gearbox and the gear shafts to the superstructure. As such, the operator can switch flexibly between diesel-hydraulic power and electro-hydraulic power.

The drive concept of the LTM 1150-5.4E is based on the Liebherr LTC 1050-3.1E compact crane, albeit with an important upgrade: an integrated battery pack. This concept brings two key advantages. Firstly, the crane can be operated autonomously for around four hours without a power connection thanks to its battery. Secondly, even a low connected load, around 16 or 32 Amps, is enough to unleash the crane’s full power since the battery acts as an efficient buffer.

The crane draws high current strengths for peaks in performance from the battery, which is constantly recharged via the site’s power source. Charging takes place via the CEE high-current plug with 16, 32 or 64 Amps and up to 44 kW of power or via a modern CCS plug for fast charging at up to 80 kW.

The 99-kWh battery is securely installed in a box weighing around 1.5 t at the rear of the crane. To enable driving on public roads, the ballast plates have been adapted accordingly – a carefully thought-out concept for maximum flexibility and efficiency on the construction site.

With the telescopic boom extended to its maximum length, the LTM 1150-5.4E can lift 9.1 t, making it suitable for erecting tower cranes and radio masts. On the construction site, the five-axle mobile crane can be immediately ready for use, since it already carries 9 t of ballast with a total weight of 60 t. This means it can carry out many jobs without requiring additional vehicles for the transport of ballast.